Peb txhawb peb cov neeg yuav khoom nrog cov khoom lag luam zoo tshaj plaws thiab cov tuam txhab qib siab. Los ua cov chaw tsim khoom tshwj xeeb hauv cov haujlwm no, peb tau txais txiaj ntsig kev ua haujlwm zoo hauv kev tsim thiab tswj kev tsim tshwj xeeb rau Xov Tooj Case Ua Tshuab Txhaj Tshuaj Molding Tshuab, Siv zog ua kom tau txais kev ua tiav tas mus li txiav txim siab los ntawm kev ua tau zoo tshaj plaws, kev ntseeg siab, kev ncaj ncees, thiab ua tiav kev nkag siab ntawm kev lag luam dynamics.

Peb txhawb peb cov neeg yuav khoom nrog cov khoom lag luam zoo tshaj plaws thiab cov tuam txhab qib siab. Ua cov chaw tsim khoom tshwj xeeb hauv cov haujlwm no, peb tau txais kev nplua nuj ua haujlwm ua haujlwm hauv kev tsim khoom thiab tswj xyuasXov tooj Case Txhaj Moulding thiab Case Txhaj Moulding Tshuab, Peb zoo siab tos txais koj tuaj xyuas peb lub tuam txhab & Hoobkas thiab peb chav ua yeeb yam qhia ntau yam khoom thiab cov kev daws teeb meem uas yuav ua tau raws li koj qhov kev cia siab. Lub caij no, nws yooj yim mus xyuas peb lub vev xaib. Peb cov neeg ua haujlwm muag yuav sim lawv qhov zoo tshaj plaws los muab cov kev pabcuam zoo tshaj plaws rau koj. Yog tias koj xav paub ntau ntxiv, thov tsis txhob yig tiv tauj peb ntawm E-mail, fax lossis xov tooj.

Kev piav qhia

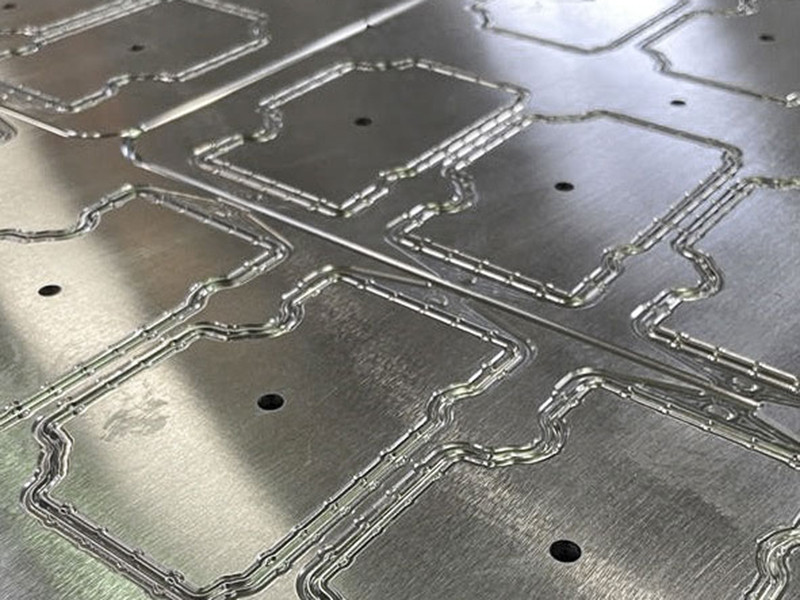

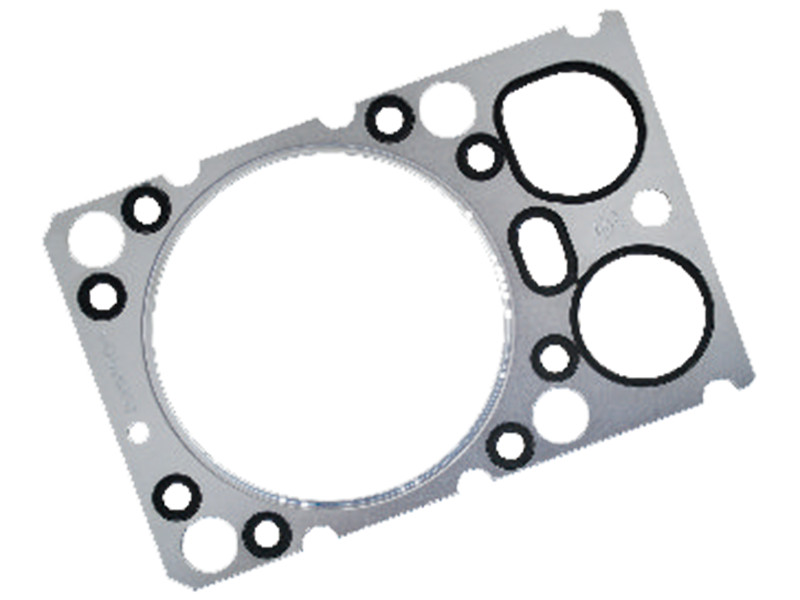

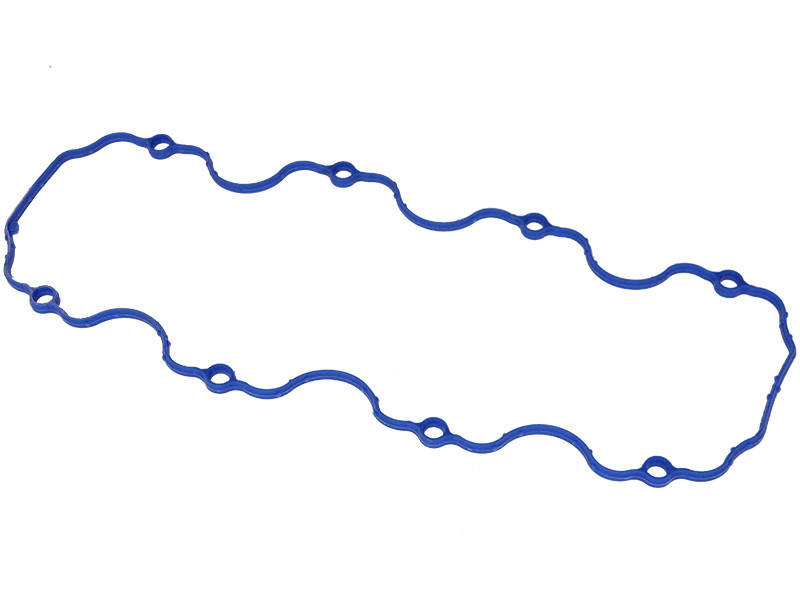

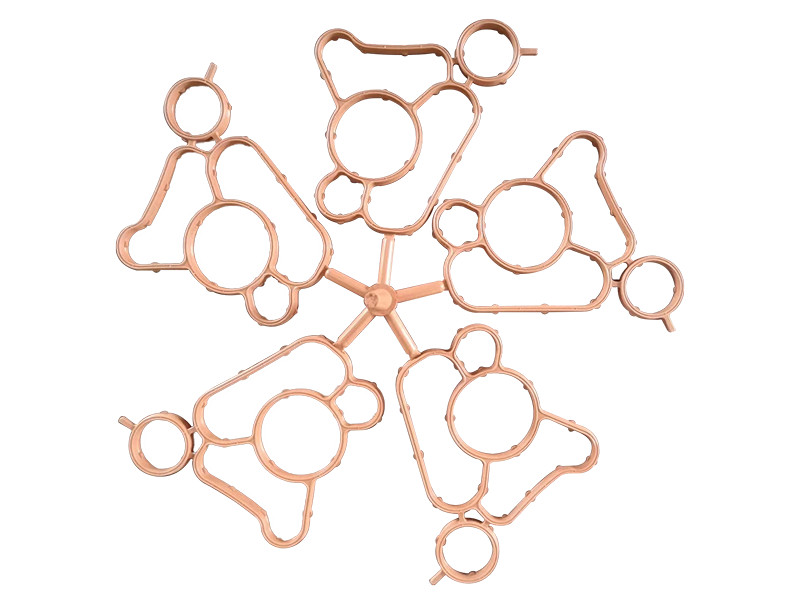

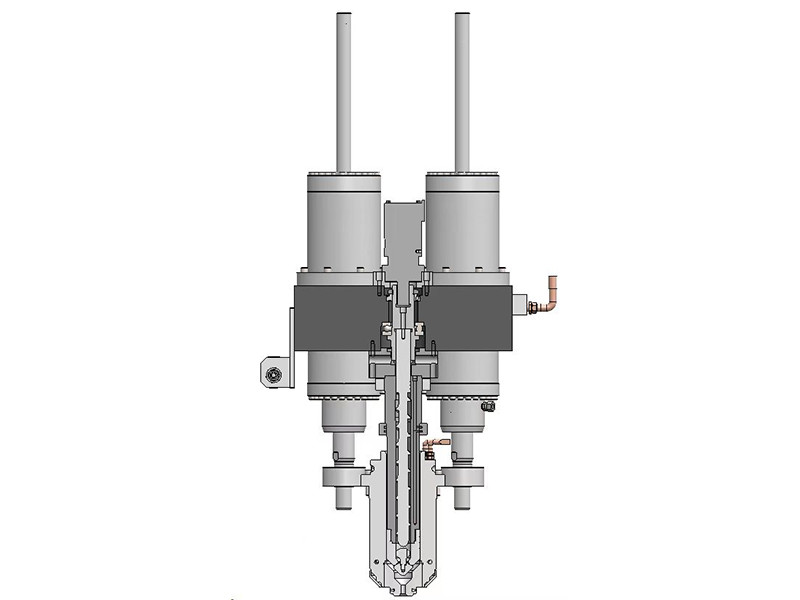

GW-RF Series FIFO Vertical Roj Hmab Txhaj Moulding Tshuab yog GOWIN High-End Rubber Moulding Tshuab Qauv. Cov cav tov tau nruab nrog VERTICAL CLAMPING SYSTEM & FIFO VERTICAL INJECTION SYSTEM, haum rau ntau yam roj hmab molded qhov chaw, tshwj xeeb tshaj yog precision roj hmab sealing khoom nyob rau hauv lub tsheb, lub zog, tsheb thauj mus los, kev lag luam, kev kho mob thiab cov khoom siv hauv tsev, thiab lwm yam.

Nrog rau kev ua haujlwm siab ntawm FIFO Txhaj Tshuaj, Roj Hmab Moulding Tshuab muaj kom haum rau txhua yam roj hmab molding xws li NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, thiab lwm yam.

Nrog High-end SERVO SYSTEM, Roj Hmab Moulding Tshuab zoo heev txhim kho kev tsim khoom thiab txo cov nqi zog. Nws yog ib lub tswv yim ntawm Roj Hmab Moulding Tshuab Qauv nrog automation roj hmab molding. Tsis tas li ntawd, Lub Tshuab Roj Hmab yog muaj rau KUB RUNNER Mould & COLD RUNNER BLOCK SYSTEM Mould (optional solutions for CRB pwm).

GW-RF Main Specification

| Qauv | GW-R120F | GW-R160F | GW-R250F | GW-R300F | ||||

| Clamping quab yuam (KN) | 1200 | 1600 | 2500 | 3000 | ||||

| Pwm Qhib Stroke (mm) | 450 | 500 | 500 | 500 | ||||

| Platen Loj (mm) | 430 × 500 hli | 500 × 500 | 560 × 630 hli | 600 × 700 / 600 × 800 | ||||

| Txhaj Volume (cc) | 1000 | 1000 | 500 | 1000 | 2000 | 500 | 1000 | 2000 |

| Txhaj Zog (bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Qauv | GW-R400F | GW-R550F | GW-R650F | ||||||

| Clamping quab yuam (KN) | 4000 | 5 500 | 6 500 | ||||||

| Pwm Qhib Stroke (mm) | 600 | 600 | 700 | ||||||

| Platen Loj (mm) | 700 × 800 hli | 850 × 1000 hli | 950 × 1000 hli | ||||||

| Txhaj Volume (cc) | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 |

| Txhaj Zog (bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

| Thawv | GW-R120F | GW-R160F | GW-R250F |

| 20 GP ib | 1 unit | 1 unit | 1 unit |

| 40 HQ | 3 units | 3 units | 2 units |

| Ntim | Pob 1: Roj Hmab Tshuab Lub Cev Lub Cev; | ||

| Pob 2: Roj Hmab Tshuab Txhaj Tshuaj | |||

| Thawv | GW-R550F | GW-R650F |

| 20 GP ib | - | - |

| 40 HQ | 1 unit | 1 unit |

| Ntim | Pob 1: Moulding Tshuab Lub Cev Lub Cev; | |

| Pob 2: Moulding Tshuab Txhaj Tshuaj | ||

Lub ntsiab nta

● Txhaj Txhaj

● Modular-design & Multi-combinations Solutions

● Lub txaj qis & Cov qauv zoo tshaj plaws

● Humanized Operating System

● High-efficiency & High-stability & High-Energy-Saving Servo Hydraulic System

Txhaj Tshuaj

● FIFO Txhaj Tshuaj, Tsiv-Lub tog raj kheej ntsug txhaj tshuaj

● High-speed & High-pressure & High-precision txhaj tshuaj

● Short Injection Nozzle Design, Kev txhaj tshuaj tsawg dua

● Muaj rau Ntau Cov Roj Hmab Tshwj Xeeb xws li VITON

Peb txhawb peb cov neeg yuav khoom nrog cov khoom lag luam zoo tshaj plaws thiab cov tuam txhab qib siab. Los ua cov chaw tsim khoom tshwj xeeb hauv cov haujlwm no, peb tau txais txiaj ntsig kev ua haujlwm zoo hauv kev tsim thiab tswj kev tsim tshwj xeeb rau Xov Tooj Case Ua Tshuab Txhaj Tshuaj Molding Tshuab, Siv zog ua kom tau txais kev ua tiav tas mus li txiav txim siab los ntawm kev ua tau zoo tshaj plaws, kev ntseeg siab, kev ncaj ncees, thiab ua tiav kev nkag siab ntawm kev lag luam dynamics.

Tsim tshwj xeeb rauXov tooj Case Txhaj Moulding thiab Case Txhaj Moulding Tshuab, Peb zoo siab tos txais koj tuaj xyuas peb lub tuam txhab & Hoobkas thiab peb chav ua yeeb yam qhia ntau yam khoom thiab cov kev daws teeb meem uas yuav ua tau raws li koj qhov kev cia siab. Lub caij no, nws yooj yim mus xyuas peb lub vev xaib. Peb cov neeg ua haujlwm muag yuav sim lawv qhov zoo tshaj plaws los muab cov kev pabcuam zoo tshaj plaws rau koj. Yog tias koj xav paub ntau ntxiv, thov tsis txhob yig tiv tauj peb ntawm E-mail, fax lossis xov tooj.