Taw qhia

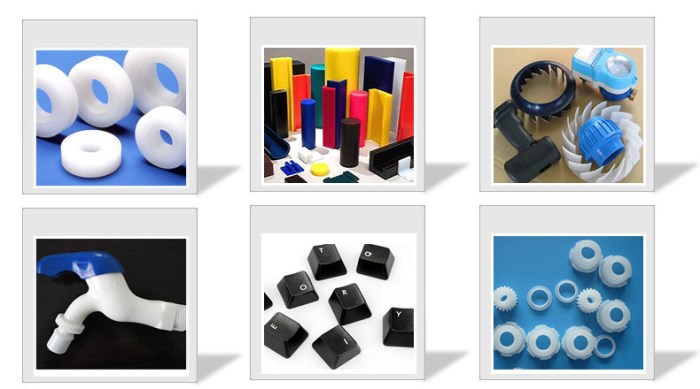

Yas thiab roj hmab txhaj tshuaj molding occupies ib tug tseem ceeb txoj hauj lwm nyob rau hauv niaj hnub manufacturing kev lag luam. Txawm hais tias nws yog cov khoom siv yas hauv lub neej niaj hnub, lossis cov khoom siv roj hmab dav siv hauv kev lag luam, kev txhaj tshuaj molding tshuab plays lub luag haujlwm tseem ceeb. Kab lus no yog tsom mus rau qhov sib txawv ntawm cov yas thiab roj hmab txhaj tshuaj molding los pab cov neeg nyeem kom nkag siab zoo dua ob txoj kev tsim khoom tseem ceeb no.

Yas txhaj tshuaj molding yog txheej txheem uas molten yas yog txhaj rau hauv pwm, uas yog txias thiab solidified los tsim ib yam khoom zoo. Raws li kev txheeb cais, tus naj npawb ntawm cov khoom yas tsim los ntawm cov yas txhaj tshuaj molding nyob hauv lub ntiaj teb yog loj heev txhua xyoo. Piv txwv li, ntau cov khoom siv yas siv los ntawm cov tuam txhab tsheb, xws li cov khoom siv sab hauv, cov pob zeb, thiab lwm yam, yog tsim los ntawm cov yas txhaj tshuaj molding.

Roj hmab txhaj moldingyog txhaj cov khoom siv roj hmab rau hauv pwm, tom qab vulcanization thiab lwm yam txheej txheem, ua kom muaj ntau yam khoom siv roj hmab. Cov khoom siv roj hmab kuj tau siv dav hauv tsheb, tshuab, hluav taws xob thiab lwm yam haujlwm. Piv txwv li, tsheb log tsheb, cov ntsaws ruaj ruaj, thiab lwm yam, yog cov khoom siv ntawm cov roj hmab txhaj tshuaj molding.

Qhov tseem ceeb ntawm ob txoj kev txhaj tshuaj molding tsis yog tsuas yog tias lawv tuaj yeem tsim cov khoom zoo nrog cov duab nyuaj, tab sis kuj tseem tuaj yeem ua kom cov khoom raug thiab cov khoom zoo. Los ntawm kev tswj xyuas qhov tsis zoo xws li qhov kub thiab txias, siab thiab lub sijhawm thaum txhaj tshuaj, cov khoom lag luam nrog qhov raug siab thiab qhov zoo ntawm qhov chaw tuaj yeem tsim tau. Nyob rau tib lub sijhawm, ob txheej txheem no kuj muaj qhov zoo ntawm kev ua haujlwm siab thiab tus nqi qis, thiab tuaj yeem ua tau raws li qhov xav tau ntawm cov khoom loj.

Txheej txheem cej luam ntawm cov yas txhaj tshuaj molding

(1) txheej txheem txheej txheem thiab ntws

Cov txheej txheem txheej txheem ntawm kev txhaj tshuaj molding yog ntxiv granular lossis hmoov yas raw cov ntaub ntawv rau lub hopper ntawm lub tshuab txhaj tshuaj, cov ntaub ntawv raw yog rhuab thiab melted nyob rau hauv ib tug ntws lub xeev, tsav los ntawm cov ntsia hlau los yog piston ntawm lub tshuab txhaj tshuaj, los ntawm lub nozzle thiab lub pouring system ntawm pwm mus rau hauv lub pwm kab noj hniav, thiab txias thiab solidified nyob rau hauv lub pwm kab noj hniav.

Cov txheej txheem tshwj xeeb feem ntau suav nrog cov kauj ruam hauv qab no: Ua ntej, kev npaj cov khoom siv raw, raws li cov khoom xav tau los xaiv cov khoom siv yas tsim nyog, xws li polystyrene, polyethylene, polypropylene thiab lwm yam. Cov khoom siv raw no feem ntau muaj cov yam ntxwv sib txawv, xws li lub zog, toughness, kub tsis kam, thiab lwm yam, kom tau raws li cov kev xav tau ntawm cov khoom sib txawv. Tom qab ntawd cov khoom siv raw yog ntxiv rau lub tshuab txhaj tshuaj rau cua sov thiab melting, nyob rau hauv cov txheej txheem no, nws yog ib qho tsim nyog yuav tsum nruj me ntsis tswj cov cua sov kub, feem ntau, cov khoom siv yas sib txawv muaj qhov sib txawv ntawm qhov kub thiab txias. Piv txwv li, lub melting kub ntawm polyethylene feem ntau yog nyob nruab nrab ntawm 120 ° C -140 ° C, thaum lub melting kub ntawm polystyrene yog hais txog 180 ° C -220 ° C.

Thaum cov khoom siv raw yog yaj thiab ntws, nws raug thawb los ntawm cov ntsia hlau lossis piston ntawm lub tshuab txhaj tshuaj rau hauv pwm kab noj hniav los ntawm lub nozzle thiab cov txheej txheem ntawm cov pwm. Hauv cov txheej txheem no, qhov kev txhaj tshuaj siab yog qhov tseem ceeb, uas yuav tsum muaj qhov loj txaus kom kov yeej qhov kev tawm tsam ntawm cov yaj thaum lub sijhawm ntws thiab xyuas kom meej tias cov yaj tuaj yeem sau cov kab noj hniav. Feem ntau, kev txhaj tshuaj siab tuaj yeem nyob nruab nrab ntawm kaum mus rau pua pua mpa.

Thaum kawg, nyob rau hauv lub txias theem, cov yas yog txias thiab solidified nyob rau hauv lub pwm kab noj hniav los ntawm lub txias system ntawm pwm. Qhov ntev ntawm lub sijhawm txias yog nyob ntawm hom yas, thickness ntawm cov khoom thiab lwm yam. Feem ntau hais lus, lub sijhawm txias ntawm cov khoom nyias nyias yog luv, uas yuav nyob nruab nrab ntawm kaum vib nas this thiab ob peb feeb; Lub sijhawm txias ntawm cov khoom tuab yuav raug ncua raws li.

(2) Cov yam ntxwv thiab qhov zoo

Yas txhaj tshuaj molding muaj ntau yam ntxwv thiab zoo. Ua ntej, nws tuaj yeem ua cov duab nyuaj. Vim hais tias cov yas muaj fluidity zoo nyob rau hauv lub molten lub xeev, nws muaj peev xwm yuav tau sau nrog complex puab kab noj hniav, thiaj li mus tsim cov khoom yas nrog ntau yam complex duab, xws li cov khoom nrog cov kab noj hniav thiab rov qab qauv.

Qhov thib ob, qhov precision yog siab dua. Los ntawm kev tswj hwm qhov tsis zoo xws li qhov kub thiab txias, siab thiab lub sijhawm thaum lub sijhawm txhaj tshuaj, cov khoom lag luam uas muaj qhov tseeb siab tuaj yeem tsim tau, thiab qhov ntev ntev tuaj yeem tswj tau ntawm ob peb mus rau kaum ob ntawm cov xov hlau. Piv txwv li, qee cov khoom siv hluav taws xob cov khoom siv hluav taws xob tuaj yeem ua tiav qhov kev xav tau qhov tseeb ntawm cov yas txhaj tshuaj molding.

Tsis tas li ntawd, cov yas txhaj tshuaj pwm muaj ntau yam, haum rau ntau hom kev lag luam ua lag luam. Cov pwm txhaj tshuaj sib txawv tuaj yeem tsim rau cov khoom sib txawv raws li lawv cov duab, qhov loj me thiab kev ua haujlwm. Ntxiv mus, kev txhaj tshuaj pwm tuaj yeem ua tau ntau yam, nrog rau kev ua haujlwm siab, thiab tsim nyog rau ntau hom kev lag luam, xws li OEM (cov khoom tsim khoom qub) thiab ODM (tsim thawj tsim tsim).

Nyob rau tib lub sijhawm, cov yas txhaj tshuaj molding muaj ntau yam kev hloov kho. Nws tuaj yeem siv los tsim ntau yam khoom siv yas, los ntawm cov khoom siv niaj hnub xws li cov tais diav, cov khoom ua si, mus rau cov khoom lag luam xws li cov khoom siv hluav taws xob, qhov chaw pib thiab lwm yam. Raws li kev txheeb cais, kwv yees li 70% ntawm lub ntiaj teb cov khoom yas yog tsim los ntawm kev txhaj tshuaj molding.

Txheej txheem cej luam ntawm roj hmab txhaj tshuaj molding tshuab

(1) txheej txheem txheej txheem thiab ntws

Roj hmab txhaj molding tshuabyog ib hom kev siv tshuab uas xa cov ntaub ntawv mus rau hauv cov pwm los ntawm kev ua haujlwm siab ntawm cov roj hmab extruder, thiab tom qab lub siab thiab qhov kub thiab txias, cov khoom siv roj hmab yuav tsum tsim cov duab thiab qhov loj hauv pwm.

Cov txheej txheem tshwj xeeb yog raws li hauv qab no:

Kev npaj ua haujlwm: suav nrog kev tshuaj xyuas cov khoom siv roj hmab, ziab, preheating thiab lwm yam haujlwm, nrog rau kev tsim pwm, tsim khoom thiab kev debugging. Kev tshuaj xyuas ntawm cov khoom siv roj hmab yog qhov tseem ceeb los xyuas kom meej tias qhov zoo thiab kev ua haujlwm ntawm cov khoom siv raw khoom ua tau raws li cov kev xav tau ntawm cov khoom. Piv txwv li, rau qee cov khoom siv roj hmab zoo, xws li tsheb log tsheb, cov ntsaws ruaj ruaj, thiab lwm yam, nws yog ib qho tsim nyog yuav tsum xaiv cov khoom siv roj hmab zoo kom ntseeg tau tias lub zog, hnav tsis kam thiab kev laus ntawm cov khoom. Nyob rau hauv cov txheej txheem ziab thiab preheating, qhov kub thiab lub sij hawm yuav tsum tau nruj me ntsis tswj kom tsis txhob qhuav ntau dhau los yog tsis txaus preheating ntawm roj hmab raw cov ntaub ntawv. Kev tsim thiab tsim cov pwm yuav tsum tau ua tib zoo tsim raws li cov duab, qhov loj thiab kev ua tau zoo ntawm cov khoom kom ntseeg tau qhov raug thiab zoo ntawm cov pwm.

Khoom siv: Cov khoom siv roj hmab qhuav tau ntxiv rau cov roj hmab extruder, thiab cov khoom siv tau raug kho ua ntej los ntawm cov txheej txheem xws li cua sov thiab extrusion. Nyob rau hauv cov txheej txheem no, kev ua tau zoo thiab parameter Chaw ntawm cov roj hmab extruder yog qhov tseem ceeb heev. Piv txwv li, qhov kub ntawm lub extruder, ntsia hlau ceev thiab lwm yam tsis zoo yuav cuam tshuam ncaj qha rau cov nyhuv plasticizing thiab zoo ntawm cov khoom siv roj hmab. Feem ntau hais lus, qhov kub ntawm lub extruder tuaj yeem nyob nruab nrab ntawm 100 ° C thiab 150 ° C, thiab cov ntsia hlau ceev tuaj yeem nyob nruab nrab ntawm kaum mus rau pua pua ntawm kev hloov pauv ib feeb, thiab cov kev txwv tshwj xeeb yuav tsum tau kho raws li hom thiab kev ua haujlwm ntawm cov khoom siv roj hmab.

Moulding: Cov khoom siv roj hmab uas tau kho ua ntej yog pub rau hauv pwm los ntawm lub tshuab txhaj tshuaj rau cov txheej txheem molding. Nyob rau lub sijhawm no, qee qhov siab thiab qhov kub thiab txias yuav tsum tau txuas nrog ua kom cov roj hmab raw khoom tsim cov khoom ntawm qhov xav tau cov duab thiab qhov loj me. Lub siab thiab kub hauv cov txheej txheem molding yog qhov tseem ceeb, qhov siab feem ntau tuaj yeem nyob nruab nrab ntawm kaum mus rau pua pua mpa, thiab qhov kub tuaj yeem nyob nruab nrab ntawm 150 ° C thiab 200 ° C. Cov khoom siv roj hmab sib txawv muaj cov kev xav tau sib txawv rau qhov siab thiab kub, piv txwv li, rau qee cov khoom siv roj hmab loj, xws li roj hmab nruas cov ntxaij vab tshaus, choj shock absorbers, thiab lwm yam., siab dua thiab kub yog xav tau los xyuas kom meej cov khoom zoo.

Compression demoulding: Tom qab molding tiav, nws yuav tsum tau txias thiab demoulding kom tshem tawm cov khoom siv roj hmab los ntawm pwm. Cov txheej txheem txias yuav tsum tau ua kom maj mam kom tsis txhob deformation lossis tawg ntawm cov khoom vim qhov kub hloov pauv sai. Ceev faj thaum demoulding kom tsis txhob ua rau cov khoom puas.

(2) Cov yam ntxwv thiab qhov zoo

Muaj peev xwm ntau lawm: tib lub peev xwm ntawm cov roj hmab txhaj tshuaj molding tshuab yog feem ntau ntawm kaum ntawm grams thiab ob peb kilograms, uas zoo heev txhim kho cov khoom tiav ntawm cov khoom tiav.

Cov khoom lag luam siab: Cov roj hmab txhaj tshuaj molding tshuab tuaj yeem tswj qhov kub thiab txias, siab thiab lwm yam khoom siv thaum lub sij hawm molding txheej txheem, yog li txhim kho qhov tseeb ntawm cov khoom.

Lub voj voog molding luv: Vim tias cov roj hmab txhaj tshuaj tuaj yeem tsim ntau yam khoom tib lub sijhawm, thiab lub peev xwm ntau lawm yog qhov loj, lub voj voog molding kuj luv. Piv txwv li, hauv kev tsim khoom ntawm qee qhov chaw pib, kev siv cov roj hmab txhaj tshuaj molding txheej txheem tuaj yeem txhim kho kev tsim khoom thiab ua kom lub voj voog luv luv.

Cov khoom zoo ntawm cov khoom tiav: roj hmab txhaj tshuaj molding tuaj yeem txo cov khoom lag luam vim tsis sib xws, npuas thiab lwm yam teeb meem, kom cov khoom zoo tuaj yeem txhim kho zoo heev. Piv txwv li, automotive seals uas tsim los ntawm cov txheej txheem roj hmab txhaj tshuaj molding muaj kev sib khi zoo thiab hnav tsis kam, uas tuaj yeem txhim kho kev ua tau zoo thiab kev pabcuam lub neej ntawm tsheb.

Qhov sib txawv ntawm cov yas thiab roj hmab txhaj tshuaj molding

(1) Qhov sib txawv ntawm cov khoom siv raw khoom

Cov khoom siv raw ntawm cov yas feem ntau yog cov thermoplastic lossis thermosetting resin, uas muaj hardness thiab rigidity, thiab cov khoom siv yas sib txawv muaj cov yam ntxwv sib txawv, xws li lub zog, toughness, kub tsis kam thiab lwm yam. Piv txwv li, polyethylene muaj cov tshuaj tiv thaiv zoo thiab hluav taws xob rwb thaiv tsev, tab sis nws lub zog thiab kub tsis kam yog qhov tsawg; Polystyrene muaj pob tshab thiab hardness, tab sis nws yog nkig. Cov yam ntxwv no txiav txim siab tias cov yas yuav tsum muaj qhov kub thiab txias ntau yam thaum lub sij hawm txhaj tshuaj molding los xyuas kom meej tias cov khoom siv raw tuaj yeem yaj tag nrho thiab ntim cov pwm kab noj hniav.

Cov khoom siv raw ntawm cov roj hmab yog cov roj hmab ntuj lossis cov roj hmab hluavtaws, uas muaj elasticity thiab yooj. Roj hmab feem ntau yog mos thiab yooj yim rau deform hauv lub xeev unvulcanized, thaum nws muaj zog dua thiab hnav tsis kam tom qab vulcanization. Cov khoom elastic ntawm cov roj hmab ua rau nws yuav tsum tau coj mus rau hauv tus account lub shrinkage tus nqi thiab resilience ntawm cov khoom nyob rau hauv lub txhaj tshuaj molding txheej txheem los xyuas kom meej qhov tseeb qhov tseeb thiab cov duab stability ntawm cov khoom. Piv txwv li, thaum tsim pwm rau cov khoom siv roj hmab, nws yuav tsum tau coj mus rau hauv tus account tias qhov shrinkage ntawm cov roj hmab yog loj, feem ntau ntawm 1% -5%, thaum lub shrinkage tus nqi ntawm cov yas yog feem ntau ntawm 0.5% thiab 2%.

(2) Qhov sib txawv ntawm cov txheej txheem tsis ua haujlwm

Hais txog qhov kub thiab txias, qhov kub ntawm cov yas txhaj tshuaj molding feem ntau yog siab dua, thiab cov khoom siv yas sib txawv muaj qhov sib txawv ntawm qhov kub thiab txias. Piv txwv li, lub melting kub ntawm polyethylene feem ntau yog nyob nruab nrab ntawm 120 ° C thiab 140 ° C, thiab melting kub ntawm polystyrene yog hais txog 180 ° C thiab 220 ° C. Qhov kub ntawm cov roj hmab txhaj tshuaj molding yog tsawg, feem ntau ntawm 100 ° C thiab 200 ° C, thiab qhov tshwj xeeb kub yog nyob ntawm hom thiab kev ua tau zoo ntawm cov roj hmab. Piv txwv li, vulcanization kub ntawm cov roj hmab ntuj yog feem ntau ntawm 140 ° C thiab 160 ° C, thiab vulcanization kub ntawm hluavtaws roj hmab yuav txawv.

Nyob rau hauv cov nqe lus ntawm lub siab, yas txhaj molding yuav tsum tau ib tug siab txhaj tshuaj, feem ntau ntawm kaum mus rau pua pua ntawm mpa, kom kov yeej cov tsis kam ntawm cov yaj nyob rau hauv cov txheej txheem ntws thiab xyuas kom meej tias cov yaj tuaj yeem sau cov kab noj hniav. Lub siab ntawm cov roj hmab txhaj tshuaj molding yog qhov tsawg, feem ntau ntawm kaum mus rau pua pua mpa, tab sis rau qee cov khoom siv roj hmab loj, yuav tsum muaj siab dua. Piv txwv li, thaum tsim cov khoom siv roj hmab loj xws li roj hmab nruas cov ntxaij vab tshaus thiab cov khoom siv hluav taws xob txuas ntxiv, yuav tsum muaj kev kub siab los xyuas kom meej molding zoo ntawm cov khoom.

(3) Qhov sib txawv ntawm cov khoom yam ntxwv

Hais txog cov duab, yas txhaj tshuaj molding tuaj yeem tsim ntau yam khoom nrog cov duab nyuaj, xws li cov khoom siv yas nrog cov kab noj hniav, rov qab cov qauv, thiab lwm yam. Vim nws cov elasticity siab thiab saj zawg zog, cov khoom siv roj hmab feem ntau yog qhov yooj yim hauv cov duab, feem ntau cov ntsaws ruaj ruaj, log tsheb thiab lwm yam.

Hais txog qhov raug, cov yas txhaj tshuaj molding tuaj yeem tsim cov khoom lag luam nrog qhov tseeb qhov tseeb, thiab qhov ntev ntev tuaj yeem tswj tau ntawm ob peb cov xov hlau thiab kaum ob ntawm cov xov hlau. Qhov tseeb ntawm cov khoom siv roj hmab txhaj tshuaj molding yog qhov tsawg, tab sis rau qee cov khoom siv roj hmab, xws li cov ntsaws ruaj ruaj, thiab lwm yam, nws tuaj yeem ua tiav cov kev xav tau siab dua.

Hais txog kev siv, cov khoom siv yas yog siv dav hauv cov khoom siv niaj hnub, cov khoom lag luam thiab lwm yam kev lag luam, xws li cov tais diav, cov khoom ua si, lub plhaub hluav taws xob, qhov chaw pib thiab lwm yam. Cov khoom siv roj hmab yog siv rau hauv tsheb, tshuab, hluav taws xob thiab lwm yam, xws li cov log tsheb, cov ntsaws ruaj ruaj, shock absorbers thiab lwm yam.

Xaus

Muaj qhov pom tseeb qhov sib txawv ntawm cov yas thiab roj hmab txhaj tshuaj molding hauv cov khoom siv raw, cov txheej txheem tsis thiab cov yam ntxwv ntawm cov khoom.

Los ntawm qhov kev xav ntawm cov yam ntxwv ntawm cov khoom siv raw, cov khoom siv yas feem ntau yog cov thermoplastic lossis thermosetting resins, uas muaj hardness siab thiab rigidity, thiab cov yas sib txawv muaj cov khoom sib txawv. Cov khoom siv raw ntawm cov roj hmab yog cov roj hmab ntuj lossis cov roj hmab hluavtaws, uas muaj elasticity thiab yooj.

Nyob rau hauv cov nqe lus ntawm cov txheej txheem tsis, cov yas txhaj tshuaj molding kub yog siab dua, lub melting kub ntau yam ntawm cov yas sib txawv yog txawv, thiab txhaj tshuaj siab yog siab dua los xyuas kom meej tias cov yaj yog tag nrho ntawm cov pwm kab noj hniav. Roj hmab txhaj molding kub yog qhov tsawg, lub siab kuj tseem qis, tab sis cov khoom siv roj hmab loj yuav xav tau siab dua.

Cov yam ntxwv ntawm cov khoom, yas txhaj tshuaj molding tuaj yeem tsim cov khoom zoo, siab precision, dav siv hauv lub neej txhua hnub thiab kev lag luam. Vim muaj kev elasticity siab, cov khoom siv roj hmab feem ntau yog qhov yooj yim ntawm cov duab thiab qhov raug qis, tab sis cov khoom siv roj hmab ua tau zoo kuj tuaj yeem ua tau raws li qhov yuav tsum tau ua, feem ntau yog siv hauv tsheb, tshuab, hluav taws xob thiab lwm yam.

Ob txoj kev txhaj tshuaj molding no yog qhov tseem ceeb rau kev lag luam muaj feem xyuam. Hauv kev lag luam cov khoom lag luam, cov yas txhaj tshuaj molding yog qhov ua tau zoo, tus nqi qis, tuaj yeem ua tau raws li cov kev xav tau ntawm kev tsim khoom loj, thiab muab ntau yam khoom siv rau ntau yam. Hauv kev lag luam khoom lag luam roj hmab, tib lub peev xwm ntawm cov roj hmab txhaj tshuaj molding yog loj, cov khoom precision yog siab, lub voj voog molding yog luv, thiab cov khoom tiav yog cov khoom zoo, uas muab cov khoom tseem ceeb thiab cov ntsaws ruaj ruaj thiab lwm yam khoom rau lub tsheb, tshuab thiab lwm yam lag luam, ua kom muaj kev ruaj ntseg ntawm cov kev lag luam. Nyob rau hauv luv luv, yas thiab roj hmab txhaj tshuaj molding plays ib tug irreplaceable lub luag hauj lwm nyob rau hauv niaj hnub manufacturing, thiab lawv cov yam ntxwv thiab zoo kuj muab kev txhawb zog rau txoj kev loj hlob ntawm txawv industries.

Post lub sij hawm: Nov-08-2024