Nws tuaj yeem yog peb lub luag haujlwm kom txaus siab rau koj qhov kev nyiam thiab muaj peev xwm muab rau koj. Koj qhov kev txaus siab yog peb qhov khoom plig loj tshaj plaws. We're searching ahead of your visit for joint growth for Factory ua kub muag Nqus Compression Molding Roj Hmab Tshuab Vulcanization Xovxwm rau Roj Hmab Gasket Ua , Zoo siab txais tos txhua tus phooj ywg nyob sab nrauv thiab cov khw muag khoom los tsim kev koom tes nrog peb. Peb yuav muab kev ncaj ncees, zoo tshaj plaws thiab cov kev pabcuam zoo rau koj kom ua tiav koj qhov kev xav tau.

Nws tuaj yeem yog peb lub luag haujlwm kom txaus siab rau koj qhov kev nyiam thiab muaj peev xwm muab rau koj. Koj qhov kev txaus siab yog peb qhov khoom plig loj tshaj plaws. Peb tab tom nrhiav ua ntej ntawm koj mus ntsib rau kev sib koom ua ke kev loj hlob rauTuam Tshoj Roj Hmab Vulcanizing thiab Roj Hmab Nqus Vulcanizing, Peb sov siab txais tos koj patronage thiab yuav pab tau peb cov neeg muas zaub nyob rau hauv lub tsev thiab txawv teb chaws nrog cov khoom ntawm superior zoo thiab zoo heev kev pab cuam npaj rau tus qauv ntawm kev loj hlob ntxiv raws li ib txwm. Peb ntseeg tias koj yuav tau txais txiaj ntsig los ntawm peb cov kws tshaj lij sai sai.

Kev piav qhia

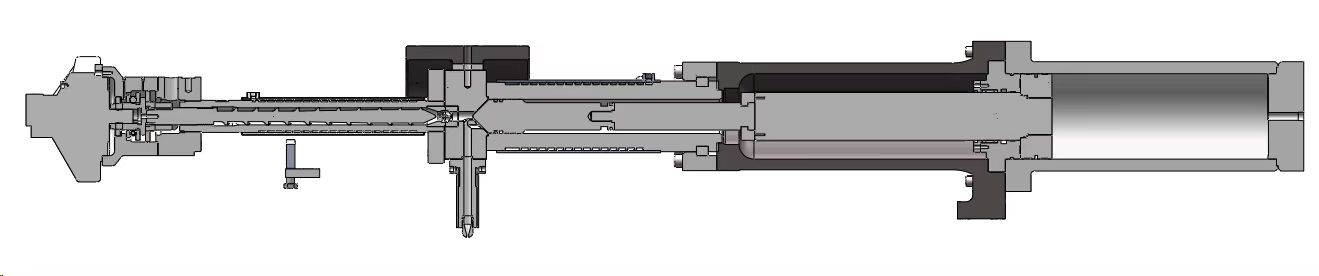

GW-SL Series Roj Hmab Txhaj Tshuaj Molding Tshuab nrog VERTICAL CLAMPING SYSTEM & FILO Angle-Type INJECTION SYSTEM yog ib qho ntawm feem nrov roj hmab Moulding tshuab hauv khw. Lub Moulding Xovxwm Ib Leeg-Tswj-Lub tog raj kheej Txhaj Tshuaj, horizontally mounting rau saum platen uas txo cov roj hmab tag nrho Xovxwm qhov siab ntau. Cov qauv roj hmab xovxwm no yog tsim rau cov neeg siv khoom uas muaj qhov txwv-qhov siab rhiav.

Tsis tas li ntawd, Cov Roj Hmab Moulding Tshuab yog tsim rau feem ntau cov roj hmab molded cov khoom lag luam hauv tsheb, lub zog, tsheb thauj mus los, kev lag luam, kev kho mob thiab khoom siv hauv tsev, thiab lwm yam. Lub Tshuab Moulding yog tsim rau ntau yam roj hmab sib txuas xws li NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, thiab lwm yam.

Roj Hmab Txhaj Moulding Tshuab zoo heev txhim kho kev tsim khoom thiab txo cov nqi zog piv nrog cov tsoos compression xovxwm.

GW-SL Main Specification

| Qauv | GW-S120L | GW-S160L | GW-S250L | GW-S300L | GW-S400L | ||||

| Clamping quab yuam (KN) | 1200 | 1600 | 2500 | 3000 | 4000 | ||||

| Pwm Qhib Stroke (mm) | 450 | 500 | 500 | 500 | 600 | ||||

| Platen Loj (mm) | 430 × 500 hli | 500 × 500 | 560 × 630 hli | 600 × 700 / 600 × 800 | 700 × 800 hli | ||||

| Txhaj Volume (cc) | 1000 | 1000 | 1000 | 2000 | 3000 | 3000 | 5000 | 5000 | 8000 |

| Txhaj Zog (bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Qauv | GW-S550L | GW-S650L | GW-S800L | GW-S1200L | ||||

| Clamping quab yuam (KN) | 5 500 | 6 500 | 8000 | 12000 | ||||

| Pwm Qhib Stroke (mm) | 600 | 700 | 700 | 800 | ||||

| Platen Loj (mm) | 850 × 1000 hli | 950 × 1000 hli | 950 × 1000 hli | 1200 × 1300 hli | ||||

| Txhaj Volume (cc) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Txhaj Zog (bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

| Thawv | GW-S120L | GW-S160L | GW-S250L | GW-S300L | GW-S400L |

| 20 GP ib | 1 unit | 1 unit | 1 unit | - | - |

| 40 HQ | 3 units | 3 units | 2 units | 2 units | 2 units |

| Ntim | Pob 1: Roj Hmab Txhaj Moulding Tshuab Lub Cev Lub Cev; | ||||

| Pob 2: Roj Hmab Txhaj Moulding Tshuab Txhaj Tshuaj | |||||

| Thawv | GW-S550L | GW-S650L | GW-S800L | GW-S1200L |

| 20 GP ib | - | - | - | 1 unit (ib qho 40HQ + ib 20GP) |

| 40 HQ | 1 unit | 1 unit | 1 unit | |

| Ntim | Pob 1: Txhaj Moulding Tshuab Lub Cev Lub Cev; | |||

| Pob 2: Txhaj Moulding Tshuab Txhaj Tshuaj | ||||

Lub ntsiab nta

● Vertical Clamping Unit & Angle-type Injection Unit

● High-pressure & High-precision Txhaj Tshuaj

● Modular-tsim & Ntau-combinations Solution

● Tsawg Tag Nrho Qhov Siab

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Txhaj Tshuaj

● 1. FILO Txhaj Tshuaj, qhov siab pub roj hmab qis.

● 2. Tib-Fixed-Lub tog raj kheej Txhaj tshuaj, Kab rov tav Mounting rau saum Platen.

● 3. Kev txhaj tshuaj ruaj khov thiab siab txhaj tshuaj raug & ruaj khov

● 4. Cov roj txias txias zoo rau SCREW & BARREL kom ntseeg tau tias kev ua haujlwm zoo ntawm cov roj hmab sib xyaw.

Nws tuaj yeem yog peb lub luag haujlwm kom txaus siab rau koj qhov kev nyiam thiab muaj peev xwm muab rau koj. Koj qhov kev txaus siab yog peb qhov khoom plig loj tshaj plaws. We're searching ahead of your visit for joint growth for Factory ua kub muag Nqus Compression Molding Roj Hmab Tshuab Vulcanization Xovxwm rau Roj Hmab Gasket Ua , Zoo siab txais tos txhua tus phooj ywg nyob sab nrauv thiab cov khw muag khoom los tsim kev koom tes nrog peb. Peb yuav muab kev ncaj ncees, zoo tshaj plaws thiab cov kev pabcuam zoo rau koj kom ua tiav koj qhov kev xav tau.

Factory ua kub-muagTuam Tshoj Roj Hmab Vulcanizing thiab Roj Hmab Nqus Vulcanizing, Peb sov siab txais tos koj patronage thiab yuav pab tau peb cov neeg muas zaub nyob rau hauv lub tsev thiab txawv teb chaws nrog cov khoom ntawm superior zoo thiab zoo heev kev pab cuam npaj rau tus qauv ntawm kev loj hlob ntxiv raws li ib txwm. Peb ntseeg tias koj yuav tau txais txiaj ntsig los ntawm peb cov kws tshaj lij sai sai.